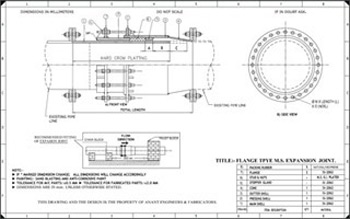

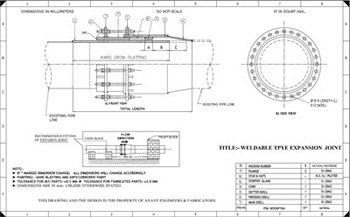

Fabricated Steel Mechanical Slip Type Expansion Joints

Section 1 : General

Sec. 1.1 Scope

This standard describes fabricated steel mechanical Slip Type Expansion Joints having packing chambers for use on pipe with plain, flanged, grooved, or shouldered ends in nominal pipe sizes from 3 in. through 144 in. (75 mm through 3,600 mm): The joints shall be manufactured from steel and are intended for use in systems conveying water. Mechanical expansion joints are not intended for use in buried conditions.

See. 1.2 Purpose

The purpose of this standard is to provide purchasers, manufacturers, and constructors with the minimum requirements for fabricated steel mechanical slip- type expansion joints, including system components, testing, and marking requirements.

Sec. 1.3 Application

This standard can be referenced in specifications for purchasing and receiving fabricated steel' mechanical Slip Type Expansion Joints and can be used as a guide for inspection and testing. This standard or sections of this standard apply when this document has been referenced and then only to fabricated steel mechanical Slip Type Expansion Joints.

Section 2: References

This standard references the following documents. In their latest editions, they form a part of this standard to the extent specified within the standard. In any case of conflict, the requirements of this standard shall prevail.

- ANS(/AWWA C200-Steel Water Pipe-6 In. (150 mm) and Larger.

- ANSIIAWWA C210-Liquid-Epoxy Coating Systems for the Interior and Exterior of Steel Water Pipelines.

- ANSIIAWWA C213-Fusion-Bonded Epoxy Coating for the Interior and Exterior of Steel Water Pipelines.

- ANSIIAWWA C218-Coating the Exterior of Above ground Steel Water Pipelines and Fittings.

- ANSII AWWA C220-Stainless-Steel Pipe, 4 In. (100 mrn) and Larger.

- ANSIIAWWA C224-Two-Layer Nylon-II-Based Polyamide Coating System for the Interior and Exterior of Steel Water Pipe, Connections, Fittings, and Special Sections.

- ANSIIAWWA C550-Protective Interior Coatings for Valves and Hydrants.

- ASMEt Bl.I-Unified Inch Screw Threads.

- ASME B 1. 13M-Metric Screw Threads-M Profile.

- ASME B 18.2. I-Square and Hex Bolts and Screws Inch Series.

- ASME BI8.2.2-Square and Hex Nuts.

- ASME B 18.2.3.6M-Metric Heavy Hex Bolts.

- ASME B 18.2.4.6M~Metric Heavy Hex Nuts.

- ASME Boiler and Pressure Vessel Code, Section IX.

Section 3: Definitions

The following definitions shall apply in this standard:

- Actual outside diameter: The pipe outside diameter. The diameter of the finished product m~y vary from the actual diameter by the specified tolerances and coating thickness.

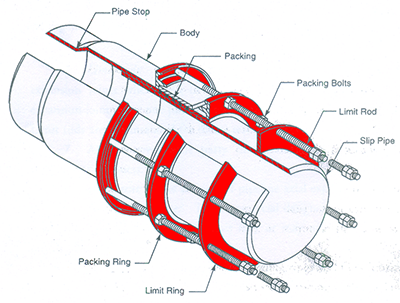

- Body: The main housing assembly includes the packing chamber and bolt ring. One end of the body is attached to the pipeline.

- Constructor: The party that provides the work and materials for placement or installation.

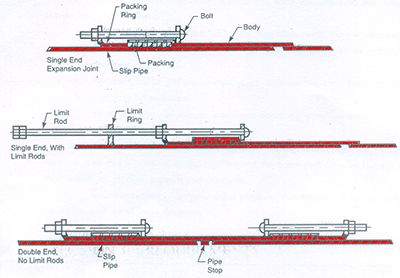

- Expansion joint: An assembly that allows compensation for axial move-ment of a water-conveying pipeline. An expansion joint may be single or double ended, with one slip pipe and packing chamber or twO slip pipes and packing chambers, respectively (Figures 1 and 2).

- Limit ring: A ring or other fixture attached to the slip pipe through which the limit rods pass.

- Limit rods: Threaded fasteners used to limit the expansion travel of the expansion joints when used in series. The limit rods will activate the adjacent expansion joint when one joint has reached the full limit of its travel (see limit ring). Limit rods are not intended for thrust restraint.

- Manufacturer: The party that manufactures, fabricates, or produces materials or products.

- Movement: The amount of pipeline axial expansion or contraction.

- Nominal Pipe Size: The commercial designation or dimension by which pipe is designated for simplicity. This mayor may not be the same as the actual outside diameter.

- Packing: Alternating elasrorneric sealing rings and fiber lubricating rings.

- Packing Bolts: Threaded fasteners used to compress the packing materials of the expansion joint.

- Packing chamber: A cavity between the body and slip pipe into which the packing is compressed.

- Packing ring: A cylinder with bolt ring that, with the packing bolts, provides a means of compressing the packing. Also referred to as an end ring, follower, or packing gland.

- Purchaser: The person, company, or organization that purchases any materials or work to be performed.

- Rated pressure: Maximum sustained operating pressure under normal operating conditions.

- Slip pipe: A cylinder that provides a sealing surface for the packing material. One end is attached to the pipeline and the other end slides in and out of the body as the pipeline expands and contracts.

- Transient pressure: Surge or other pressures that exceed normal operating conditions and are of short duration.